6S Audit Template

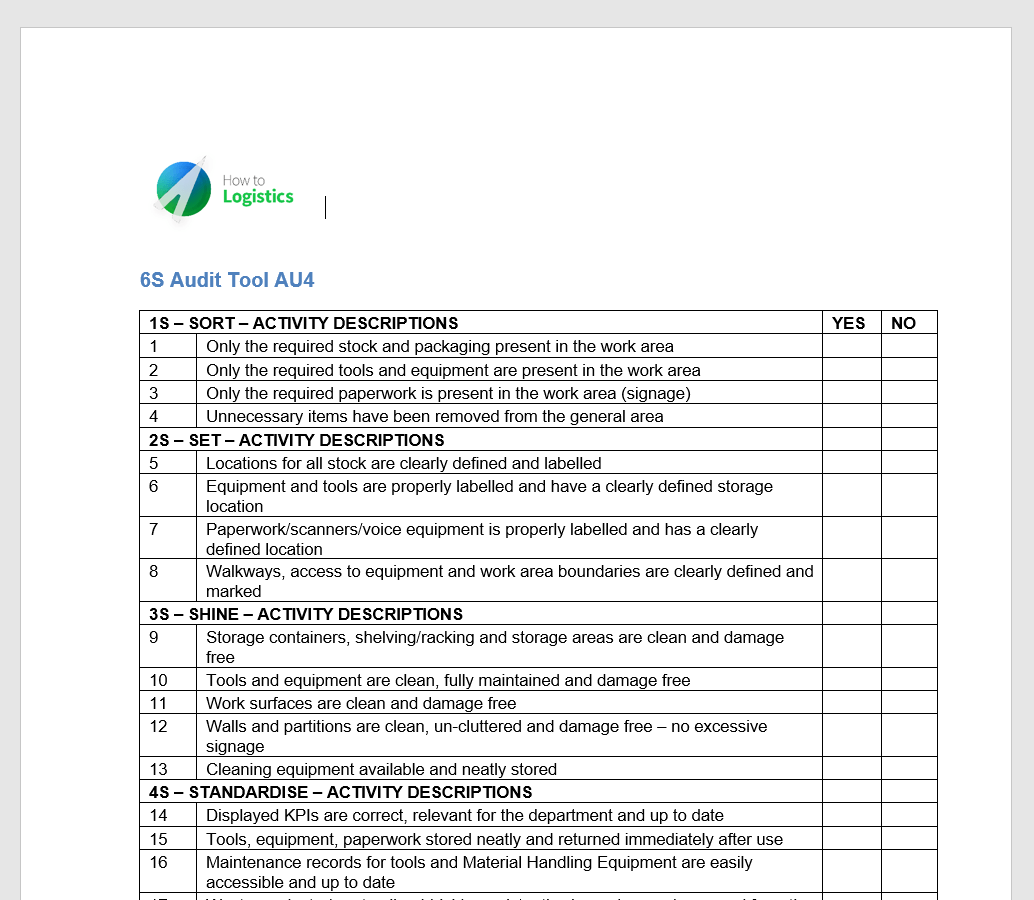

6S Audit Template - Use this template periodically to inspect the quality and safety practices in your manufacturing, logistics and other work. You should seek your own professional advice to. A 6s audit checklist for manufacturing is a comprehensive tool used to assess workplace organization and cleanliness. Use this 6s audit sheet to evaluate and improve your organization and the cleanliness of your workspace. The document is an audit template for assessing compliance with 6s (sort, set in order, shine, standardize, sustain, safety) methodology. Worksheets are audit work safety, 6 s checklist of ys 25 date, 6s audit a, sbs 6s visual management wi. Use this 6s audit checklist as a template to improve workplace safety and efficiency, by evaluating the 6 steps of the lean process in your facilities. Improve continuously cleanliness, order, safety, quality, and efficiency. Up to $50 cash back start by gathering all necessary materials and resources for conducting the 6s checklist. Begin the checklist by assessing the workplace for potential safety hazards. Use this 6s audit sheet to evaluate and improve your organization and the cleanliness of your workspace. It contains sections to evaluate if only necessary. The templates are intended to be used as hypothetical examples only and should not be used as a substitute for professional advice. Sort, set in order, shine,. The 6s audit checklist consists of six key elements that, when implemented effectively, can transform the way businesses operate, ensuring they remain competitive and efficient in. The document is a checklist for auditing a manufacturing area using 6s. Use this 6s audit checklist as a template to improve workplace safety and efficiency, by evaluating the 6 steps of the lean process in your facilities. A 6s audit is basically a 5s audit with extra attention to safety. The document is an audit template for assessing compliance with 6s (sort, set in order, shine, standardize, sustain, safety) methodology. Worksheets are audit work safety, 6 s checklist of ys 25 date, 6s audit a, sbs 6s visual management wi. The checklist includes six key areas: Sort, set in order, shine,. Begin the checklist by assessing the workplace for potential safety hazards. Improve continuously cleanliness, order, safety, quality, and efficiency. A 6s audit checklist for manufacturing is a comprehensive tool used to assess workplace organization and cleanliness. Browse the public library of over 100,000 free editable checklists for all industries. Sort, set in order, shine,. The templates are intended to be used as hypothetical examples only and should not be used as a substitute for professional advice. A 6s audit checklist for manufacturing is a comprehensive tool used to assess workplace organization and cleanliness. Up to $50. It contains sections to evaluate if only necessary. Browse the public library of over 100,000 free editable checklists for all industries. Use this template periodically to inspect the quality and safety practices in your manufacturing, logistics and other work. The 6s audit checklist consists of six key elements that, when implemented effectively, can transform the way businesses operate, ensuring they. Use this template periodically to inspect the quality and safety practices in your manufacturing, logistics and other work. The document is an audit template for assessing compliance with 6s (sort, set in order, shine, standardize, sustain, safety) methodology. By applying the 6s’ you will organize, eliminate unneeded materials and enable. Sort, set in order, shine,. It contains sections to evaluate. Use this 6s audit checklist as a template to improve workplace safety and efficiency, by evaluating the 6 steps of the lean process in your facilities. Up to $50 cash back start by gathering all necessary materials and resources for conducting the 6s checklist. This document contains an audit checklist for evaluating a work area according to 6s methodology (sort,. The 6s audit checklist consists of six key elements that, when implemented effectively, can transform the way businesses operate, ensuring they remain competitive and efficient in. A 6s audit is basically a 5s audit with extra attention to safety. The document is an audit template for assessing compliance with 6s (sort, set in order, shine, standardize, sustain, safety) methodology. The. Begin the checklist by assessing the workplace for potential safety hazards. Use this 6s audit sheet to evaluate and improve your organization and the cleanliness of your workspace. Sort, set in order, shine,. Use this template periodically to inspect the quality and safety practices in your manufacturing, logistics and other work. The 6s audit checklist consists of six key elements. Improve continuously cleanliness, order, safety, quality, and efficiency. The document is a checklist for auditing a manufacturing area using 6s. The 6s audit checklist consists of six key elements that, when implemented effectively, can transform the way businesses operate, ensuring they remain competitive and efficient in. Begin the checklist by assessing the workplace for potential safety hazards. The templates are. Sort, set in order, shine,. Up to $50 cash back start by gathering all necessary materials and resources for conducting the 6s checklist. By applying the 6s’ you will organize, eliminate unneeded materials and enable. The 6s audit checklist consists of six key elements that, when implemented effectively, can transform the way businesses operate, ensuring they remain competitive and efficient. By applying the 6s’ you will organize, eliminate unneeded materials and enable. A 6s audit is basically a 5s audit with extra attention to safety. The checklist includes six key areas: It contains sections to evaluate if only necessary. A 6s audit checklist for manufacturing is a comprehensive tool used to assess workplace organization and cleanliness. It contains sections to evaluate if only necessary. The document is an audit template for assessing compliance with 6s (sort, set in order, shine, standardize, sustain, safety) methodology. The checklist includes six key areas: A 6s audit is basically a 5s audit with extra attention to safety. Sort, set in order, shine,. This document contains an audit checklist for evaluating a work area according to 6s methodology (sort, set in order, shine, standardize, and sustain). Use this template periodically to inspect the quality and safety practices in your manufacturing, logistics and other work. Improve continuously cleanliness, order, safety, quality, and efficiency. Use this 6s audit checklist as a template to improve workplace safety and efficiency, by evaluating the 6 steps of the lean process in your facilities. A 6s audit checklist for manufacturing is a comprehensive tool used to assess workplace organization and cleanliness. Begin the checklist by assessing the workplace for potential safety hazards. Use this 6s audit sheet to evaluate and improve your organization and the cleanliness of your workspace. You should seek your own professional advice to. View and download manufacturing 6s audit for free. The document is a checklist for auditing a manufacturing area using 6s. Up to $50 cash back start by gathering all necessary materials and resources for conducting the 6s checklist.Six Sigma 6S Diagram Template 6S Example

The 6S's of Warehouse Maintenance B.I.G. Logistics

6S Checklist Template

6S Audit Checklist DronaHQ LowCode Platform

6S Audit Sheet Personal Protective Equipment Technology

6S Audit Template Excel

6s Audit Template Complete with ease airSlate SignNow

Jenis 6S Audit Checklist

6S Audit Draft) Lean Manufacturing Audit

6s Audit Checklist PDF Personal Protective Equipment Safety, 60 OFF

The Templates Are Intended To Be Used As Hypothetical Examples Only And Should Not Be Used As A Substitute For Professional Advice.

By Applying The 6S’ You Will Organize, Eliminate Unneeded Materials And Enable.

Browse The Public Library Of Over 100,000 Free Editable Checklists For All Industries.

The 6S Audit Checklist Consists Of Six Key Elements That, When Implemented Effectively, Can Transform The Way Businesses Operate, Ensuring They Remain Competitive And Efficient In.

Related Post: